“Oh… The Disbelievers”

There I was being asked questions about 3d printing at an event recently. Then the ultimate question came out, “how long does it take to make one of these things?”

“From start to water and racing … about a week”, I said. There was this half disguised look of disbelief and some polite chuckles in the background. It reminded me of the one minute mile myth… once Bannister broke it something like 30 others did so in the coming year. Tipping points matter.

Well, that was a nice challenge. I came away from my “friends’ thinking this could be fun. But I didn’t get a chance to follow through for a couple of months until a new tipping point came with the discovery of a brilliant new PLA filament from e-SUN called PLA+. This material has basically been a peak experience for myself and the research over the last 2 years. It is a big step forward in our goal to approach and hopefully surpass the resilience of fiberglass construction.

An article called “A Breakthrough” can be found in “Whats New” in this menu. In summary, this PLA+ has the following advantages:

- Stiffer

- Better surface finish than normal PLA and nearly as good as PET-G

- Prints at a slightly higher temperature (due to it’s higher hardness I presume)

- Basically shatter proof if printed properly (see hammer test)

- Very tough, scratch resistant surface

- Less chance of warping in long flat sections

- Harder to cut and sand (a good property)

All in all, a VERY impressive new product.

So here was my excuse. After convincing myself that this was real with a bunch of tests, I now yearned for some new boats for the coming State Titles. I had the designs from Bill, all the hull testing had been done, internal bits designed. The rigs and keel/bulb were ready… could I do a boat in a week?

Then the thought came.. can I do TWO boats in 7 days.

Let’s see if I could put together an IOM and a 10R alongside of each other?

I went to sailing on the Wednesday and then focused on two new boats sailing the following Wednesday. Nothing had been printed at that point.

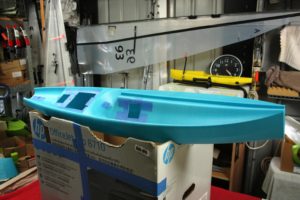

Day 1: Printed the blue IOM from the PLA+

Day 2: Printed the yellow 10R from PLA+ and called it “10 Bananas”. We had visitors most of the day from Canberra. Thank goodness the printer doesn’t need me while printing.

Day 3: Printed the bits and pieces for both boats. A lot of common items. Went Saturday sailing today, didn’t say anything about the challenge. Wet and windy, came home early. Started preparing for installation and gluing the bits on the boats.

Day 4: Continued installation and gluing.

Day 5: Continued installation, the slowest part is waiting for the epoxy to go off so one can rotate the hull and do the other side.

Day 6: Excellent zero wind conditions at the pond for checking the flotation of the 10R to determine the LWL and also position of the rudder. Went over at dawn and scared the sleepy pelicans.

Day 7: Did it. Pulled both boats out of the car and sailed half the day with each. It took a while for my fellow members at the club to wake up to what was being sailed in front of them. One of them asked me if I was painting my 3d boats now, he hadn’t realised it was a different boat. This was a mixed fleet day, but a good one to check for balance and basic performance.

In spite of the visitors, it wasn’t difficult to print and assemble in the 7 days. The slow part is always the epoxy.