The Story Behind “The Sabre” Development

by Bill Hagerup (USA) and Selwyn Holland (AUS)

Bill and I started conversing across the globe in late 2016 looking to step the knowledge from the RG65 research up into something more substantial like an IOM.

In bits and pieces “The Sabre” series was born. We wanted an efficiently 3d printed yacht that was also a solid performer. We could see the great benefits of bring good design experience together with quality printing.

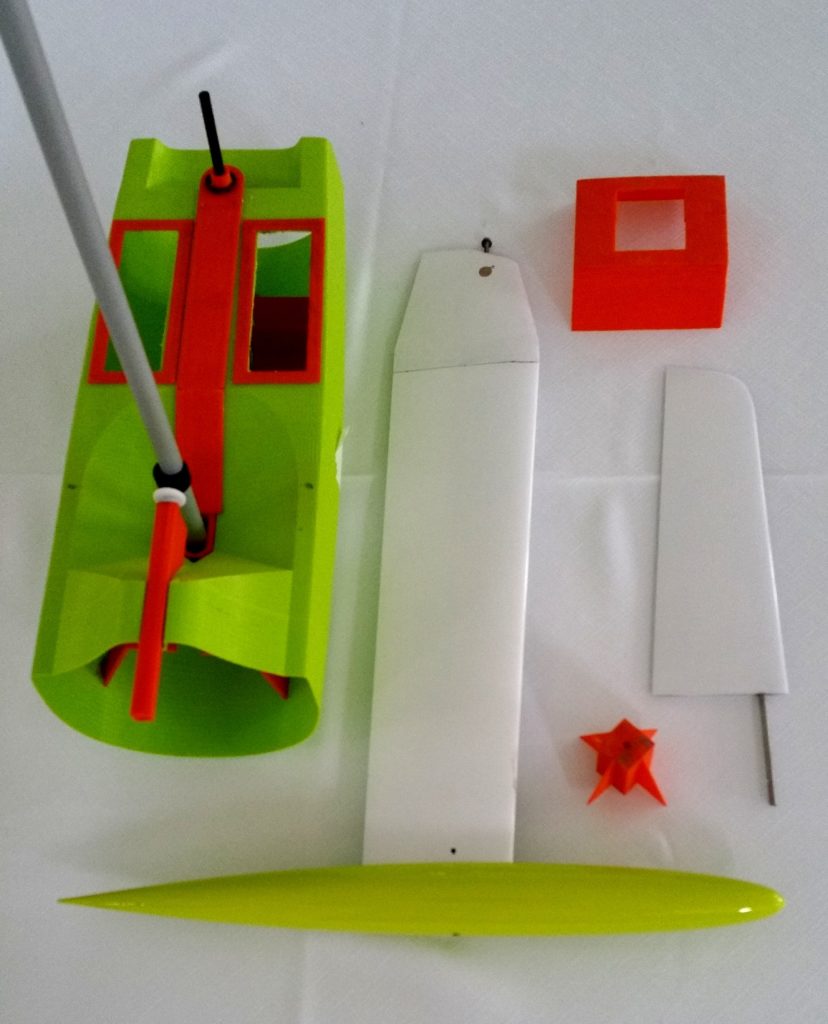

- The First Prototype

This was the initial design to test ideas, construction and materials. It was never sailed in competition, but it did quickly teach us how to proceed from here.

A multiple section design that was sleeved together after all the parts were inserted inside. Very easy to do and could be done on most amateur printers, details on this style of construction can be seen in the published papers copied at the bottom of the front page.

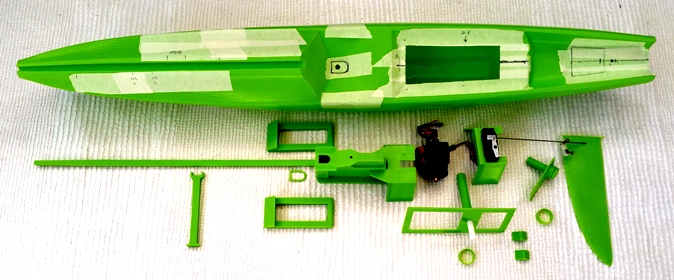

2. The Second Prototype

This was never intended to hit the water. It was a platform to test the idea of slotting keel boxes made specifically for individual keels. This means different keels can be tested on the one platform. This may be used in the future but not at the moment. Again we were encouraged by the ability to produce good design ideas overnight.

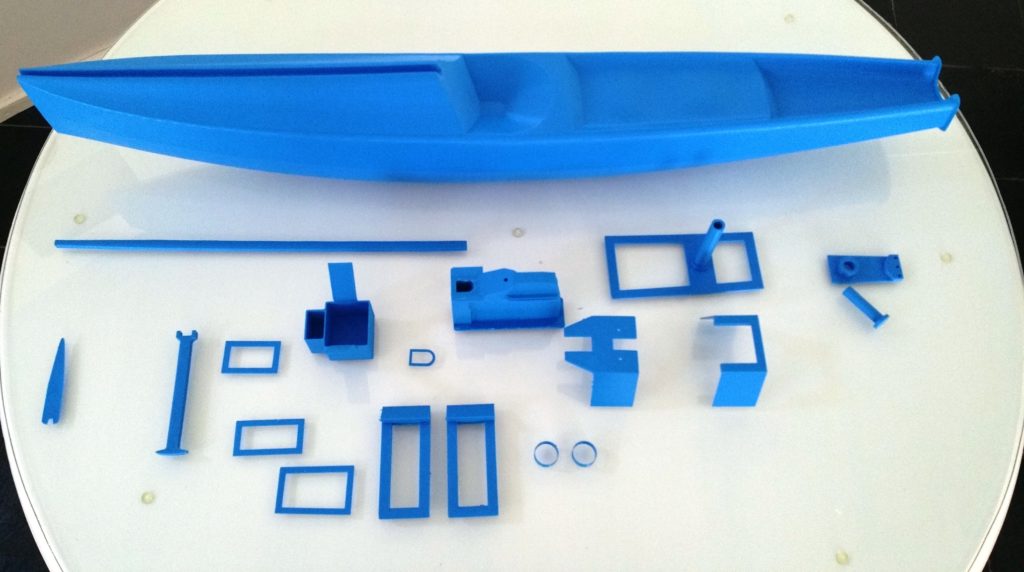

3. Alpha Sabre Was Born

By this stage we were capable of producing IOM hulls in one section. Yes, this is very convenient, but brings with it an ever increasing set of challenges. Sleeving the hull in sections is still a viable and fast way for the amateur to enter the innovative world of 3d printing.

The design then settled on a version in the RG65 series that we knew was strong, easy to produce and very competitive. It was a matter of up scaling the design to the IOM size and rules. Much easier when done digitally.

The first of the real Sabre series hit the water mid 2017 and was immediately recognised as fast, stable and very competitive across a wide range of conditions. It took us by surprise because we expected to have to go through several iterations of this design to get the “sweet spot”. No, it was competitive from the first time it hit the water.

4. Beta Sabre (yet to be born)

A slight variation on the chines lead to the next design.

This is a very pretty boat and will most likely be the design we settle on for a while now.

Another big advantage of the 3-d printed yachts is that the surface does not need any work. It is stable and finished from the moment it comes off the printer… no sanding, no painting, no chipping. Over the long term it may turn out to be a superior surface.

Yes, assuming the surface is done properly and with care, it produces a slight matte finish that is not the expected “gloss” finish. But from all our testing in the Footies, RG65s and now IOMs there does not appear to be any disadvantage. In fact it has been suggested that the natural finish could be an advantage.

Time will tell, at the moment our boats are definitely up the front with the fastest in the fleets. And have already won a number of regattas.

Alpha Sabre on the bottom and Beta Sabre on the top.

And more to come.