A Breakthrough

I am very excited about discovering a new filament on the market.

When we first started, we wanted to expose the potential of 3d printing to the Radio Controlled Yacht world beyond making a few gadgets or a plug for a fibreglass hull.

So, I went out and and learnt the 3d trade so to speak. Used my science background with a quality printer and went looking for a better way to produce hulls. The goal was:

- A surface that would be smooth enough for top level national competitive racing without sanding, painting or special preparation.

- Material that was cost effective.

- Stiff in the sense that it would not bend much under force from the rig and keel

- Resilient to scuffs and did not need painting

- Strong in the sense that it would not break

- Easy to print and non toxic

- Resilient to shattering in the sense the hull would hold up against being T-boned by a port tacker in a strong breeze

Up until this point, the main contenders have been PLA, PET-G and ABS. The comparison of these features is summarised in the sister article attached to this menu: Further Testing of Materials….

So what is this filament? How did I find it?

It is called PLA+ from e-SUN industries from China.

I found it by accident when I ordered some PET-G and simply added a roll of the PLA+ thinking it would be good to have a spare PLA for some future work.

Wow, it printed very nicely and I decided to do the standard heat/fracture/strength tests and you guessed it, the result was VERY superior.

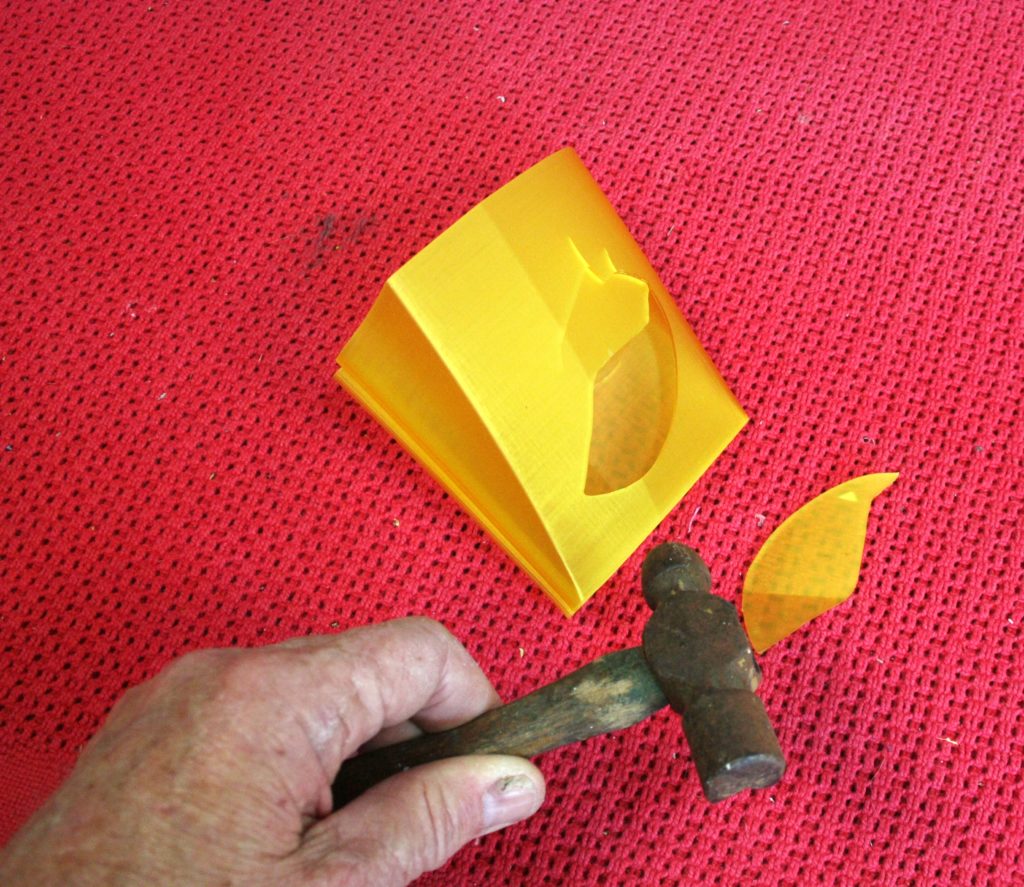

The first thing I noticed is that my rather non-scientific fracture test could not break it. I use a small round nose hammer and increase the strength of the hit until the material shatters. PET-G from e-SUN was the best up until now. This PLA+ simply would not fracture, in fact it hurt my hand. I bash it holding the surface of the hull from underneath.

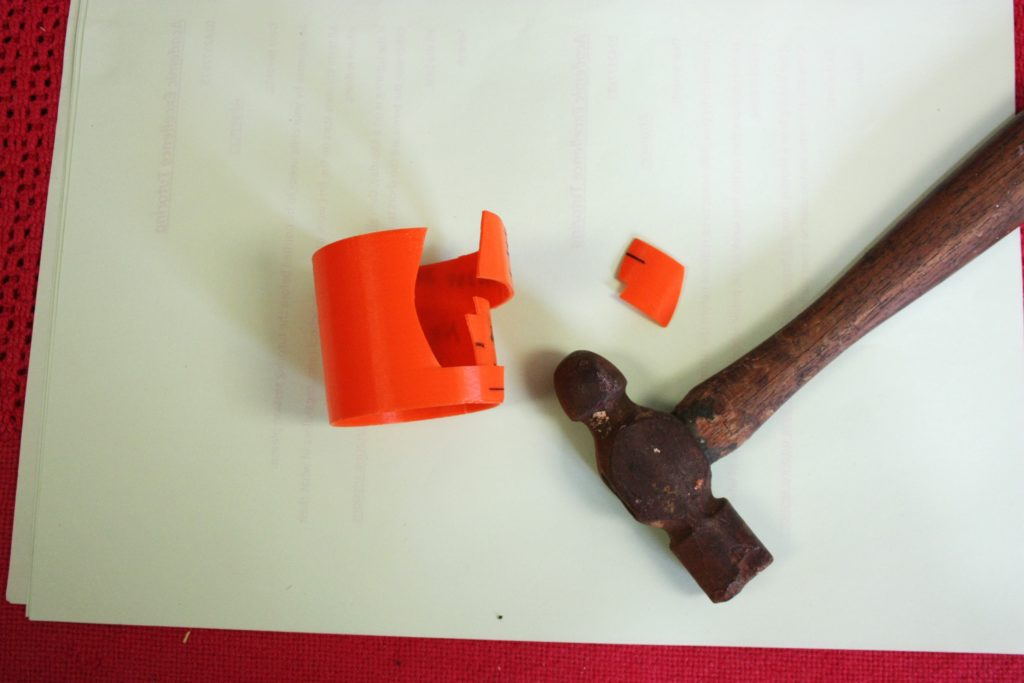

Normal PLA (this is my control each time)

PET-G (the best up until now… much better than normal PLA)

PLA+ (the second image shows the multiple hard hits it weathered but only left minor scuff marks on the surface.

I showed this to an engineer friend of mine who is the “go to man” in our club for technical matters and he thinks the hit strength achieved here would also crack a fibreglass hull. So we are now in the ball park for fracture resistance along with thin fibreglass/epoxy layers. I haven’t confirmed this yet but my sore hand gives me a gut feeling we are in the zone.

To continue this test, I started with multiple samples of different thicknesses from 1.1 mm down to 0.6mm still using the bow section of the boat. I managed to eventually crack the 0.6mm shell along one of the print layers for 2 cm but it did not fracture into bits like the images show the others will do when forced.

A small split along a layer is ultra easy to repair with some epoxy squeezed into the crack and then the excess wiped away with some metho (denatured ethanol).

The PET-G does, however, have a higher resistance to distortion as temperatures rise in a hot car. But, the PLA+ was definitely better than the normal PLA that I have used. Stating the obvious, no radio yacht should be left in a place that could become exceedingly hot anyway. I’ve seen carbon fibre parts distort from being left in a hot car.

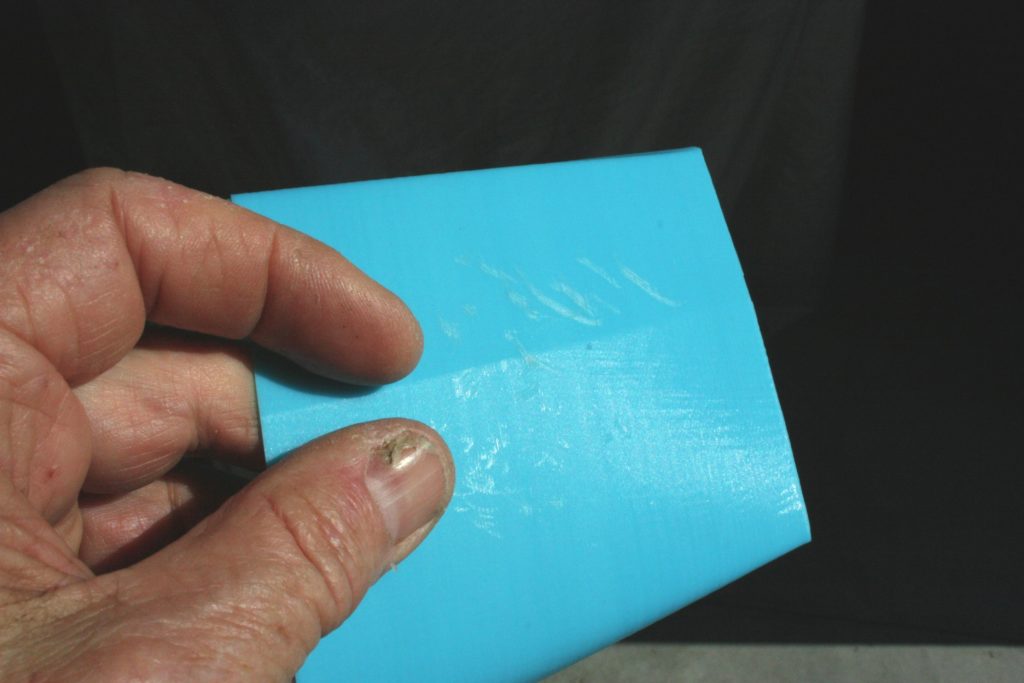

In terms of surface gloss, PLA+ seems to cling better to itself when printing compared to normal PLA giving a smoother finish. It is almost as good as PET-G which has the glossiest surface I have come across when printed correctly (see “high temperature printing” described elsewhere).

I was so impressed and encouraged, I have just now printed and assembled myself a new IOM and a 10R for the up coming NSW State Titles here in AUS. New RG65 and Nano hulls are ready to be assembled as well. This gives me a whole new set of tougher racing boats. More details on this project can be found in the “7 Day Challenge” on the menu.

This discovery makes we wonder what is coming next or what is still out there that has not been found yet. To be honest, I had basically relegated the PLA to being used as a nice material to make minor parts. I did not expect this corn derivative (yep, the common joke over here is you can eat your boat if you get angry with it) to have a new life.

Contact with the parent company was less than helpful except to tell me that when manufacturing they put a chemical in to harden it. Whatever they do to the filament, in my opinion, this is a big leap forward for 3d printing and our beautiful sport.