Introducing “Lipstick”

The Development Continues….

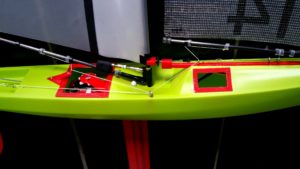

Introducing the latest RG65 from the combined efforts of Bill Hagerup and Selwyn Holland.

In fact this is an updated variation of the “Shrink” series that I have been sailing here in Australia. The “Glass Lady” was the last prototype in the series and can be viewed elsewhere in the site.

So what is different?

Mainly on the construction side:

- a slightly thicker hull for resilience (added 20g). The “Glass Lady” has had no problems on the water but I have had feedback from those constructing their own that during the building process they occasionally cracked something while cutting. Easy to fix at the time but an experiment with hull thicknesses totally solved the problem anyway. All part of the ongoing research and exposure of what we have learnt on the way. Hopefully others will be able to start in a more advanced position than what we did.

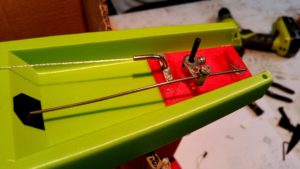

- Some minor changes to how the internal running gear fits in. The original is proving very efficient and this just added a bit to it.

- The main change was the position of the mast/keel case. This was moved back 10 mm and seems to be a slight improvement on balance/performance particularly in the heavier chop. Time will tell. The “Glass Lady” is a fast and very competitive RG and “Lipstick” is feeling just as good and so far a bit better in short chop, stronger breezes, yet still very fast in the lighter conditions. Time will tell, I can hardly wait to get it to some regattas.

- The addition of a slightly heavier 3d printed bulb and very stiff 3d printed keel to be used at those fast and furious events. As a side note, I started using a hydro-dynamically efficient 3d printed bulb a while back more as a dare to see if it could be done. It went so well that I have not bothered to take it off. I have seen no disadvantage at all compared to standard lead only bulbs and so much easier to make.

- Nothing was done to the outside surface of this model. We have discovered that the fine matte finish is no hindrance to performance and is very resilient to bumps and scraps, definitely superior to paint. So we just leave it as it is. The colour is within the printed PLA, not on the surface.

The initial trials have gone very well and this will now be my personal racing craft.

Enjoy the images.

Selwyn Holland.

Any questions can be sent to selwyn.holland2@gmail.com. Be patient, I get to them as a soon as I can. I will say I am staggered and heartened by the amount of interest and the quality of the questions coming through.

Latest update:

The more I sail it, the faster it seems to want to go. The sails are a standard jib and a rather radical double luff single sheet main. The combination of both of these seems to easily keep with and often beat both the best RG65 swing rigs and now the new A+ rig on the latest DF. The A+ has a larger surface area than the maximum Rg 65 rig.

Results from our latest Club Championship round included 2 6 1 1 2 5 1 from a strong fleet of 11 yachts. That was a comfortable overall win for the round. It is rarely out of the top three in club sailing and championships.

I can hardly wait to get it to a major RG65 competition. An earlier design won the Australia Day Regatta last year in Sydney.