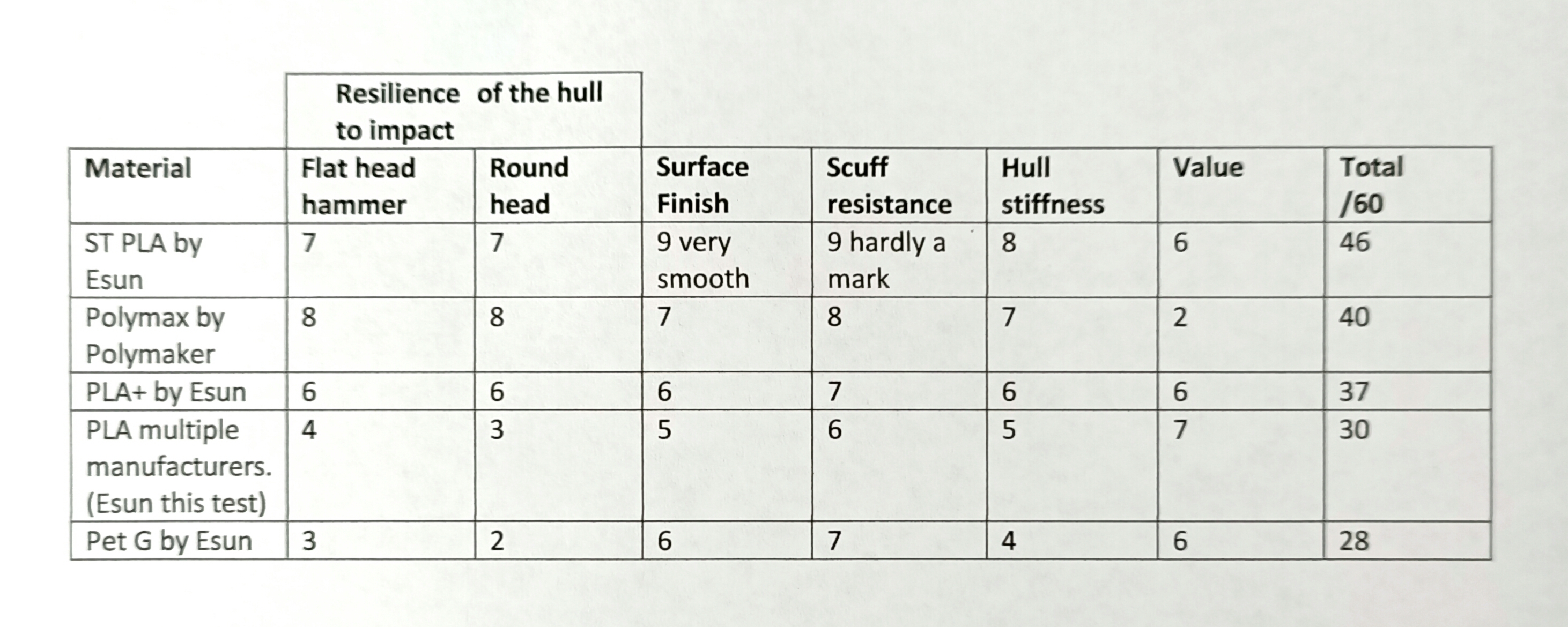

“At last… A Realistic Comparison Of The Current Best Materials That Can Be Used To Make RC Hulls and other Thin Skin Items”

Material testing for 3d printed hulls. Ranking Scale: 0 (hopeless) to 10 (the perfect material)

While there are many other possible materials for 3d printing radio yachting things, these are my picks in order using a pseudo-technical ranking system designed to search out the best properties for producing thin layer items, especially hulls for radio yachting.

This method may not sit well with some of you, but bear with me as I explain the logic of the testing process.

I know at least 3 people out there who will most likely disagree with this analysis because they are firmly entrenched in their favourite thermoplastic. But one has to make a stance at some stage and also test in such a way that it makes sense for our very special needs in building radio controlled yachts of all sizes. I have been referred to one more material that is proving hard to source, which will be added later if it turns out worthy.

There are many other materials out there from a myriad of manufacturers that I have tested. I particularly like the quality of Esun and they have recently supplied two of the top three materials for printing hulls. The Pet G was added as a comparison showing how far ahead the PLA ST was in terms of what is needed for resilient boat building.

What about the science of material studies? Why have I not followed that pathway?

I have moved away from the formal technical specifications that often comes with the materials used for manufacturing: from metals to thermoplastics. My wife is a retired metallurgist, I’m a trained geologist turned science/maths educator, so we are not unfamiliar with terms like Reynolds Numbers, Young’s Modulus, Elasticity, Tensile Strength etc.

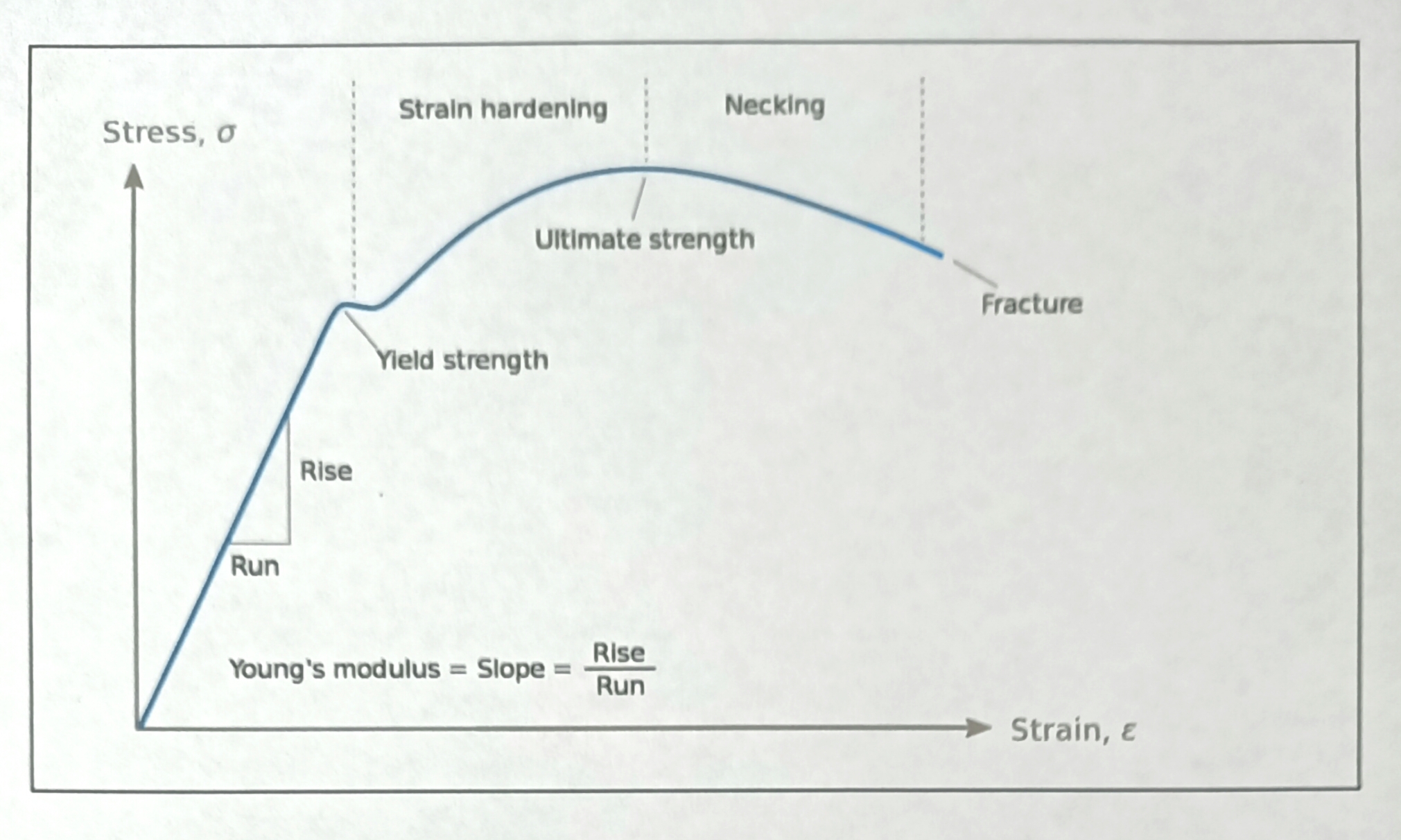

While I don’t actually use these technical terms here, for those who like the official testing here are the standard tests loosely cross referenced to those in the table above:

Young’s Modulus, linear stress versus strain. Note the diagram below. This is hard to apply to hulls because they are being bent and pressurized in all sorts of ways and many materials are perfectly appropriate until a wild boat hits you in a gust. Then you want resilience to fracture from a sharp or blunt surface on the other boat. Also, knowing the scratch resistance (scuffing) is important for most of us considering the rough and tumble of RC racing.

Young’s Modulus diagram

Tensile Strength, yield is a challenge for brittle but not ductile materials. When a material cracks, that means it has yielded to the forces applied. This is applicable to the “resilience”, as I call it, of our hulls. In a brittle material the tensile strength is close to the yield point, so it cracks suddenly and early when strong sharp forces are applied. In a ductile material the ultimate tensile strength tends to be higher and hence the yield is much later. So a hull that cracks easily (carbon fibre) is brittle but the latest thermoplastics being tested here are more ductile and can absorb sharp focused force better before breaking. Pure PLA is more brittle than either Polymax or ST PLA, which in turn, are more ductile. The reasons are complex…. from layer adhesion to what is in the thermoplastic along with the PLA.

Bending Strength, just what you want for your keels. This is a measure of stiffness. For the hulls, if the material or design allows the hull to flex then as the wind rises you will very quickly have a softish forestay vibrating. But there is a point where enough stiffness can be put into a design by using struts etc. to overcome this problem. Having said that, the stiffness (not brittleness) of these new materials is easily enough now for even the biggest RC yachts. A case in hand, is the project I did with Graham Bantock to produce the A Class Spear. Even only having the PLA+ at the time, that material was easily stiff enough to produce a fully 3d printed version that turned out to be nice and fast even compared to the best of the A Classes out there currently. No forestay slackness even with a hull 2000mm long. It was a great step forward in our understanding of what can made and be strongly competitive in radio yachting.

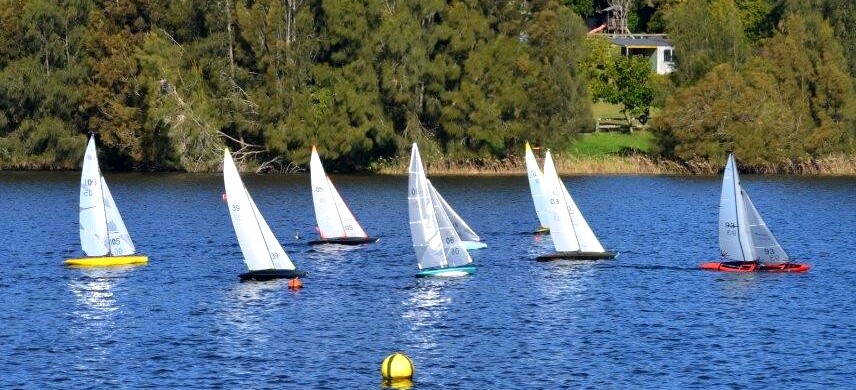

Nice and fast, the red A Class is Graham’s latest design. This prototype was 3d printed.

Impact Strength, the ability to resist scratches and scuff marks. Don’t you hate those first few dings and scratches with a new yacht? Fortunately, most 3d printing thermoplastics are very good at resisting the scuffs of racing. The newest materials are even better than all the paints I know of.

But how does all this really help us decide what is best for the hulls and fittings on our yachts?

After much consideration about this a few years back, it became obvious moving into the future, there needed to be a strong focus on the needs of the hulls more than anything else. The other bits and pieces can usually be made from most thermoplastics available. The hulls have some special needs that have only recently been more than satisfied.

So let’s focus on the HULLS, shall we? Let’s look at the features moving across the table at the beginning of this article:

- Resilience of the hull to impact. This is tested by producing a 50-100mm section of the IOM Sabre bow to beat the living daylights out of. This is all done with my very scientific and ancient flat/round nose hammer (see image). Once owned by my father, it is over 100 years old and a big favourite in the loft.

This is a basic process. Hold the bow in one hand, chose the flat side of the hammer and start hitting the hull against the open hand, softly at first, increasing the force until it cracks. Then reverse the sides of the hull and hammer and do the same with the round nose.

It is a “feel thing” but you would be surprised how much this can tell you about the resilience of the hull material. All test bows are printed the same using a 0.8 mm nozzle and settings to produce the strongest hull I can for the material being tested. All are 1.0 mm thick, the normal hull thickness I produce, with the aim being to keep the variables under control to help adhere to the scientific method.

A. Flat Face of the hammer. This represents glancing blows from other yachts on the water. Probably a bit more severe than would happen in reality, but still supplies valuable information.

B. Round Face of the hammer. This is representing a direct bow hit from another yacht (say port /starboard) with increasing speed of contact. The question is … how fast and strong does the collision have to be to cause damage that would retire a boat? It seemed obvious a sufficiently strong hit to cause a fracture would be the limit.

Both Polymax and ST PLA were very hard to crack with both sides of the hammer, making them excellent materials for hull printing. Polymax was slightly better. Pet G, as a comparison, was very brittle and would easily crack with light force. Making it the worst in these particular tests.

The test hammer and its victims

2. Surface Finish. A complex subject discussed elsewhere. A lot of time was spent trying to work though all the variables of 3d printing to settle down to those settings that produce an acceptable surface that was smooth enough to work within the Reynolds Numbers. Trialing on the water has clearly shown that a slightly corrugated 3d printed surface fresh off the printer can move through the water with as low a friction base as a gloss hull. It is all to do with the laminar flow layer and its thickness on our low speed yachts. Do some reading on it if you are not convinced.

A good finish also involves attention to detail on the mechanical motion of your printer, so you should keep and eye on the wheels, gears and chains.

Assuming you have all the good print settings and your machine is running smoothly, then the hull finish depends squarely on the thermoplastic technology. That can also be tested.

It has amazed me how far the material quality and impact strength has come in just a few years. When PLA+ from Esun hit the market in 2018, the initial testing convinced me “we had arrived”. What I mean here is the thermoplastic was now no longer a “glass ceiling” for development. There is no way we could have continued with the IOM prototypes and the mammoth 10 Raters and A Class without this PLA+. The game changed overnight. Easy to print, lovely finish, stiff and impact resistant.

But now we have Polymax and ST PLA, another big step forward.

When I tested Polymax for scuff resistance recently, it was very impressive and the best so far. Having done the same test (using the hammer of course) on the new ST PLA… what can I say, the result was simply breathtaking!

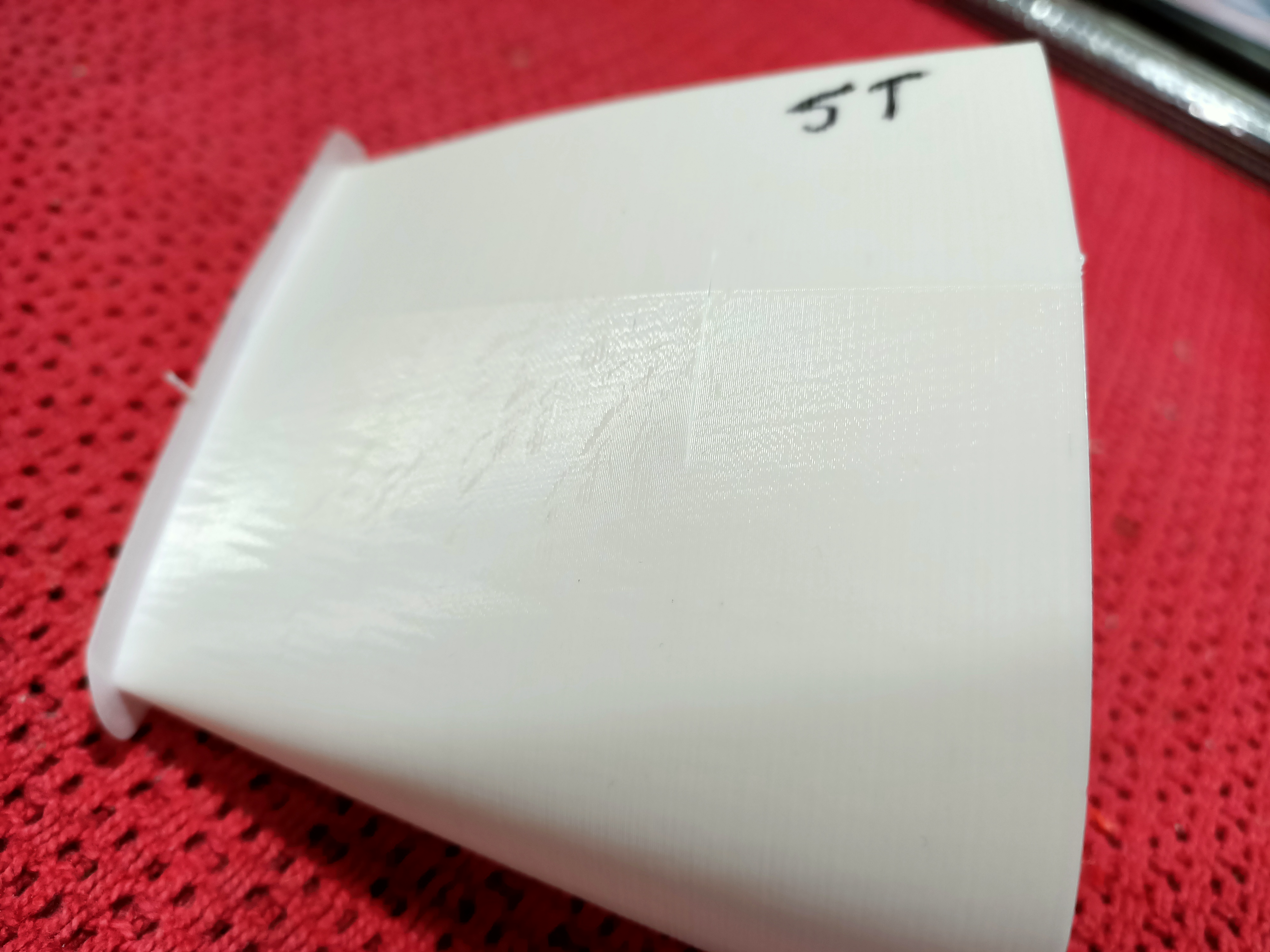

I tried to photograph the scuffs on the ST PLA, all very difficult when they are so fine. In spite of many solid impacts from the hammer, there was little evidence of scuff or scratch damage.

The marks you can see are not cracks, just scuff marks from the hammer. Tough stuff!

The scuff marks were hard to photographically show you. Even tougher than Polymax for surface resilience.

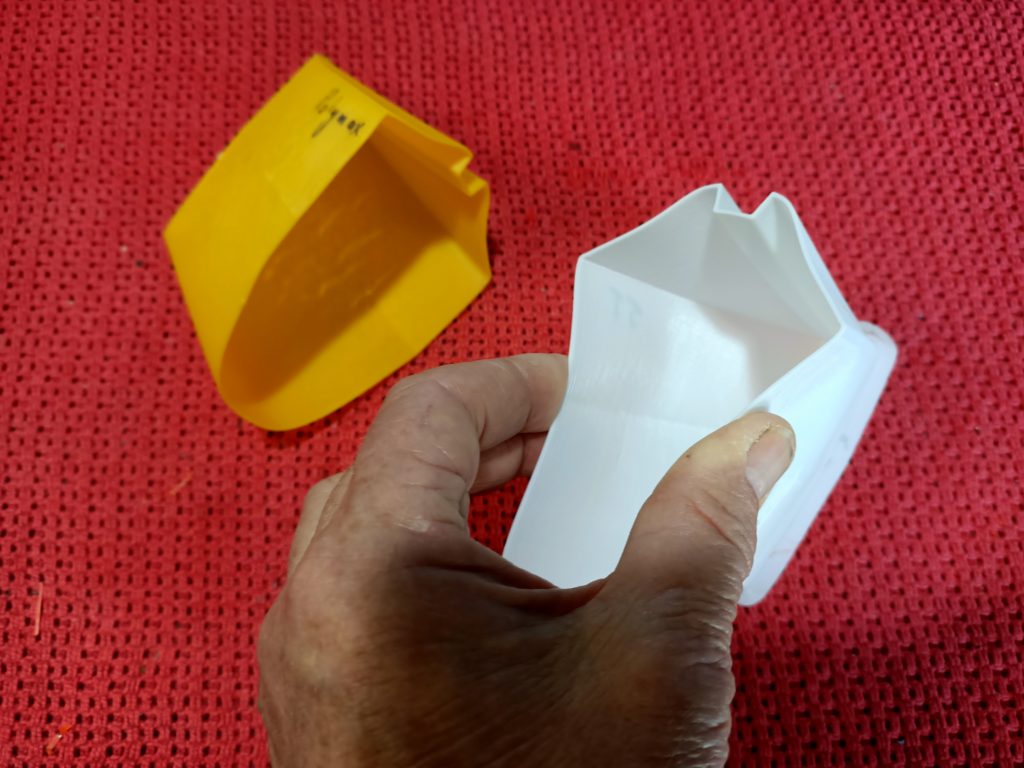

3. Hull Stiffness. As explained earlier, the stiffness of a hull is a blend of material stiffness and good hull design. The stiffness comparison of the thermoplastics involved squeezing by hand similar sized bow sections and also open cylinders to “feel” which material offered the most resistance. This might sound rather simple but the human hand can give you enough feedback to determine which sample is stiffest. It was relatively easy to rate them against each other.

This stiffness test was simply designed to rank the materials. Works really well.

To help improve the torsional (bending) strength of a hull as I’m building nowadays, I install a wooden dowel down the middle of the foredeck on all new prototypes. It enhances the stiffness of the new hull materials and guarantees the forestay is easily tight enough right up into the strong wind range. There is no real difference now to my original fiberglass hulls.

The wooden bow strut helps stiffen the forward section of the hull.

4. Cost of the thermoplastic reels. After the initial investment of machines and testing, 3d printed yachts are very good value.

The material prices per roll in AUS dollars:

ST PLA about $30 per kilo (ST stands for Super Tough)

Polymax about $80 per 750g

PLA+ about $30 per kilo

Normal PLA about $25 per kilo

Pet G about $30 per kilo

While I have your attention, here are some other factors to consider.

Have you tried to discover your optimum printing temperature?

For me this is a must for new material and any time I am starting a new reel of thermoplastic. I will say that there are only very small differences between the reels of quality manufacturers today compared to 6 or 7 years ago. In the earlier days it wasn’t uncommon to sent reels back that were faulty, but haven’t done this in recent times. I wonder how many people would blame their machine and not be aware of the possibility of poor filament?

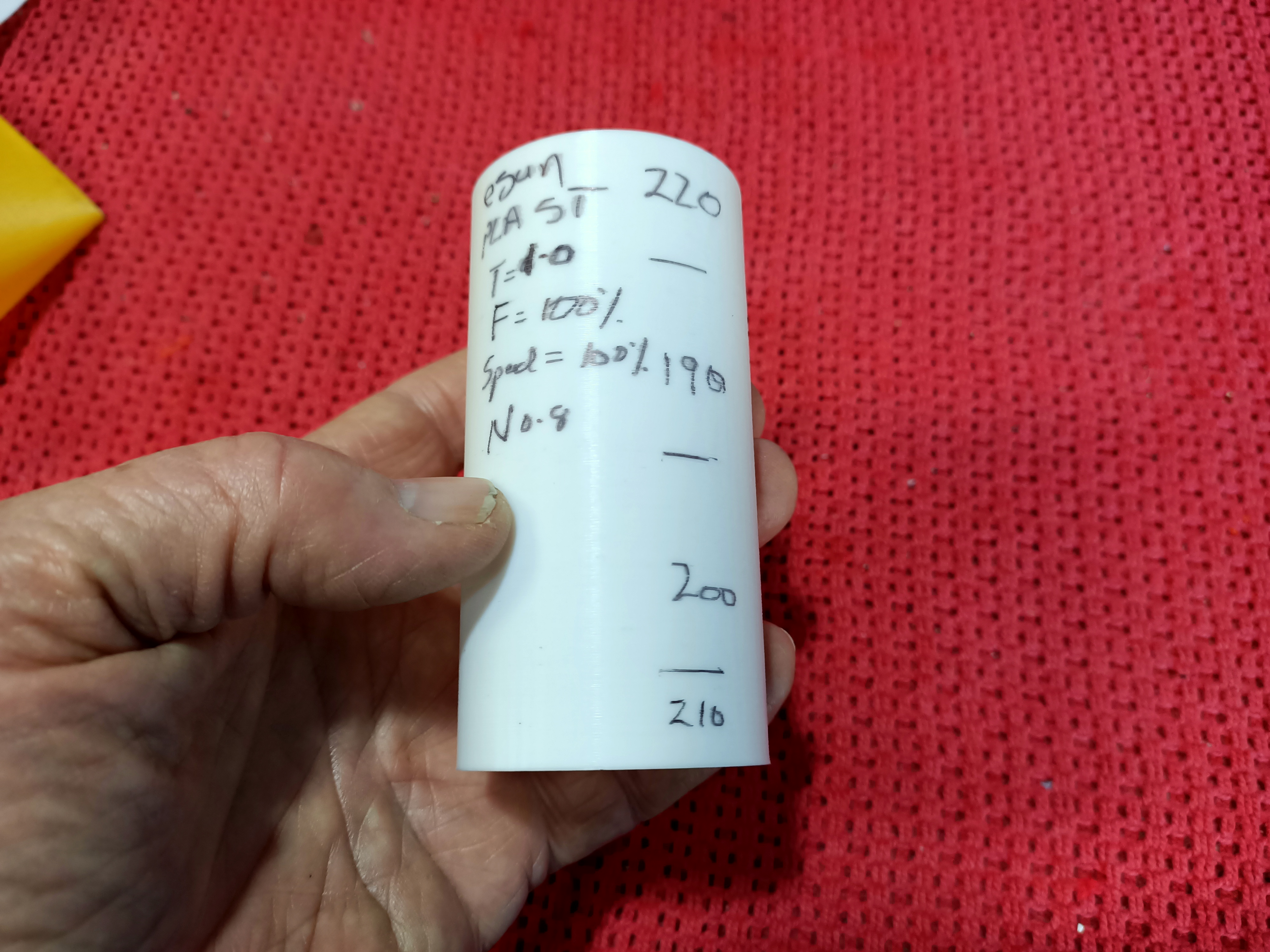

This is a pre-test that relates to the resilience and finish of the hulls. With this, you will be determining the best temperature for the thermoplastic in your machine.

Design a 50mm diameter solid tube and set the printing software for it to be open at both ends with vase (spiral) mode also set. Start printing at the suggested temperature recommended. Then vary the temperature up and down 5 to 10 deg C every now and then as it prints away. Let the tube have a couple of cms on each temperature for a good comparison. I place a horizontal texta mark on the transition zone between the temperature tests. Particularly try to work out the absolute top end temperature before the thermoplastic starts bubbling and popping (at this point it is actually starting to boil).

Personally, having found the top end temperature I almost always print around 10 degrees less. This seems to produce a lovely finish and a solid joining of the layers. All very important for strong and finely finished hulls.

Both Polymax and ST PLA were the best at this. ST PLA seemed a tad better and seemed to produce a better finish across a wider temperature range. This image displays the method.

Let the printer and filament tell you the best temperature, rather than believing the manufactured numbers.

Have you been warned about “heat warping” of 3d printed materials?

This has happened to me once and been mentioned in emails from other people who have not been aware of the “softening temperature” of thermoplastics, particularly PLA.

My case was during a regatta in a 45 deg C heat wave in the middle of summer in Australia. I had covered my new blue IOM with a white sheet as I would do with my non 3d printed boats anyway. A curious bystander wanted to have look at this weird 3d printed yacht. So, without me knowing he pulled the sheet off, looked at it and then moved on without replacing the sheet. Yep, a nice warp happened on the sunny side of the hull. It took 15 minutes but made me aware I needed to look after my boats better.

Why does this happen? Two reasons.

- PLA has a lowish fluidisation temperature.

A white surface softens at around 65 deg C from my independent testing. This is the point at which the hull will start warping and cannot be recovered. Don’t confuse these temperatures with air temperature. The Esun data sheet tells us that the heat distortion

temperature for PLA is around 60 deg. As a comparison, Pet G is around 65 deg C and ABS is even higher at 70 degrees. No mention of colour or thickness of material, hence I did my own research.

- Hull temperature is a function of air temperature, colour and colour density.

Air temperature is not the only contributor to temperature rises on the PLA. I would hope that you would not leave your boats in an enclosed car (windows up) or place them on a hot bitumen path… these are obvious. But what is not obvious is the absorption of sunlight (electromagnetic spectrum from UV to infra red) and conversion of this radiation to heat by the material. The reality is that the biggest variation amongst samples of PLA is not the PLA itself but the colours. Put your hand on a black coloured car versus a white car and you will see what I am talking about. The heat builds up quickly the darker the colour and also seemsto depend on the type of dye being used.

If your boat is in the water on a really hot day, be careful if the wind is light and it is a bit of a drifter. A boat being sailed vigorously in good breeze should have few problems because the heat can be dissipated into the water sliding past and also the cooler air close to the water. The more the wind, the cooler the air near the surface and there are good thermodynamic reasons for this. Just think about why people who live near oceans tend to have less temperature variations than those inland out in the deserts.

I have seen a number of cases where carbon fibre hulls and particularly carbon keels have warped after being neglected and left in the sun on a hot day. Unless it is winter here, I cover all my boats: fiberglass, carbon and particularly 3d printed.

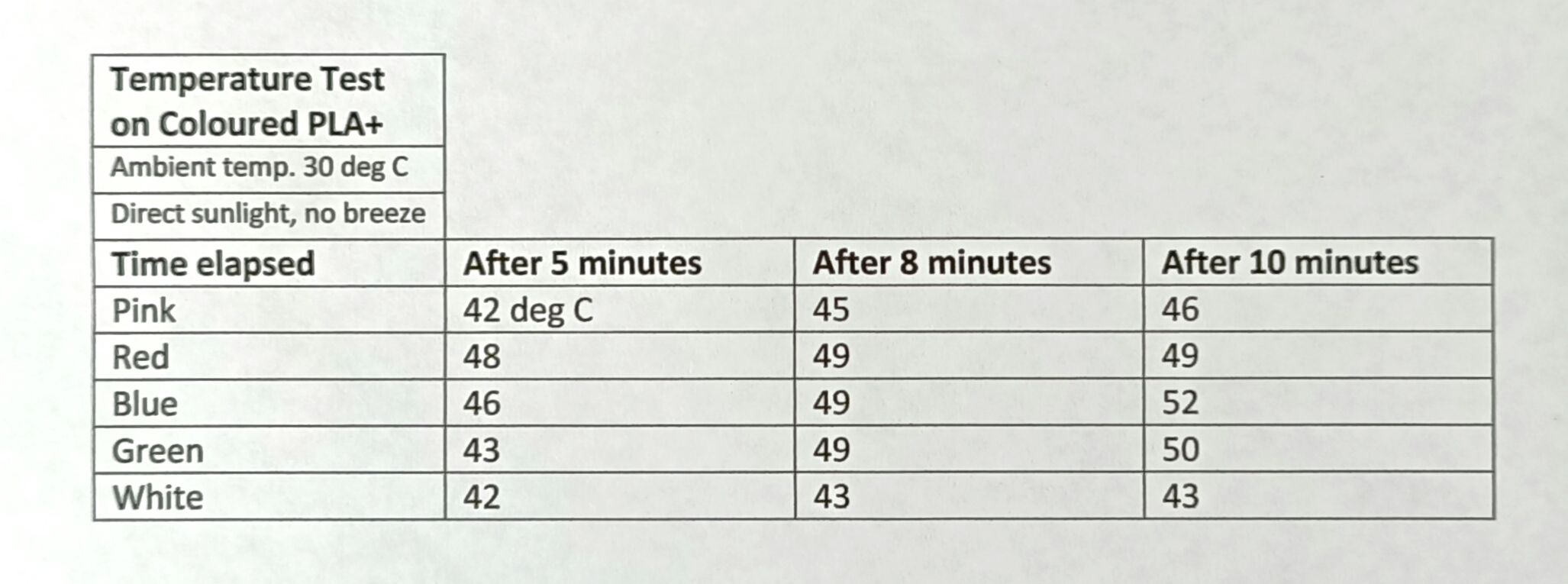

The table below shows the material surface temperature build up of some of the Esun PLA+ colours, in open sunlight on a 30 deg C day. The test samples were all the same size (50x50mm) and at a hull thickness of 1.0 mm. None of them warped or had noticeably softened after the 10 minutes. All were placed alongside each other facing towards the sun and a laser temperature reader was used for accuracy.

There a number of factors in the heating of thermoplastics.

A good recommendation from all this is to test a piece of the material you are working with for heat softening in extreme conditions so you know the approximate limit. Hopefully, this will be an insurance policy against curious bystanders playing with your boat.

With the test, I was amazed at how the light green warmed up more than the darker red. The dye type seems to make a difference as well as the colour density.

Don’t let me scare you, I have sailed my blue and red boats on very warm days with no problem. But, maybe I’ll keep a white boat aside for the “stinkers” we often get in February here in AUS.

First Results: Initial Printing with the new PLA ST from Esun

Because I had only just received the PLA ST as this article was being prepared, a hull had yet to be printed to back up what the testing was showing. But now that I’ve had time, there is an IOM Sabre PLA ST being prepared right now. There is no doubt this new material has superior qualities in terms of finish. It shows a finer finish in terms of the minor layering corrugation that comes with 3d printing.

This is more good news to keep the surface roughness well below the Reynold Numbers for laminar flow without having to sand and smooth up the hull’s surface. Also, the raw hull certainly seems naturally stiffer.

It simply looks great, very neat.

A very impressive material, both finish and stiffness. Just what we want for good hulls.

Where can you get hull designs to print?

There are a range of quality hull designs that can be sourced from the net nowadays. As well, Bill and I have made available a range of well tested hulls and boat fittings on this site. All in downloadable and ready to go STL files for free. All of the hull types have been trialed extensively and only released when we felt they had been optimized. From IOMs to Footys, there is something for everyone.

STL files are here: https://3dprintedradioyachts.com/stl-file-downloads/

In Summary.

This page will be updated from time to time as more interesting materials become available.

If you have had experience with thermoplastics other than shown here and you feel they could have good potential please let me know. I’m a sucker for trying things… all part of the fun.

Also, please feel free to tell me if you totally disagree with anything in this article. Open discussion is all good for the advancement of our beautiful sport.

Tell us about your own testing if you have done any. This method has certainly worked well for me to produce better hulls each time.

Some will disagree. But I feel the resilience of these latest hulls made from Polymax and ST PLA especially (and to an extent PLA+) will prove over time to be superior to glass fibre and carbon in terms of resilience. It is going to be hard to beat the stiffness to weight advantage of carbon fibre…. but who knows where the technological development of these thermoplastics will go from here??

Hope this has made some sense and helped you to focus more on your own special 3d printing needs.

Selwyn