Beta Sabre

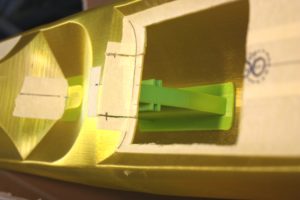

Another great design from Bill. Parallel to the other things going on in the research has been the further development of the Sabre series of club racing yachts. This one has variable deck layout making it inherently stiffer (like H beams in constructions) and a stronger, sharp full length chine.

The work done elsewhere in testing different materials (PLA plus, PETG, ABS and a few others) have been incorporated in this design to it’s advantage. I would have to say this is the best raw print finish I have achieved in any of the yachts so far. The finish is not just about machine accuracy but almost as importantly the type of material, speed of printing and the temperature of the nozzle.

But more on this later.

First day out today was in a perfect breeze 5-15 km/h against a very fast Craig Smith Fusion. I also have one of these very rare lake yachts and know how fast they are. We team matched for a couple of hours until a big storm sent us home. After a couple of short tune up races, we got serious and were hardly more than a few metres apart the whole time…. with about equal race wins. Not bad for a fresh yacht with the epoxy still curing.

First day out today was in a perfect breeze 5-15 km/h against a very fast Craig Smith Fusion. I also have one of these very rare lake yachts and know how fast they are. We team matched for a couple of hours until a big storm sent us home. After a couple of short tune up races, we got serious and were hardly more than a few metres apart the whole time…. with about equal race wins. Not bad for a fresh yacht with the epoxy still curing.

I will have to say, I was very encouraged again with another quality design from Bill.

Construction was a 24 hour print session for the hull, another day printing all the internals and then about 5 days in short spurts putting it all together. Definitely a fast way to come up with a new yacht. The slow part is waiting for each epoxy session to cure… if someone could show me how to epoxy up against gravity, I would be very interested.

The problem I am having now is selecting what boat to sail. The sister Banana series is also a strong performer.