One Foot at a Time…a Small Step for Man, a Giant Leap for Mankind

Bill Hagerup

Quest for a 3D-printed Footy…. The Story

Well, maybe I’ve exaggerated a bit. But it has been a fascinating journey to work with Selwyn to develop a 3D Footy and prove that it is a topnotch competitor.

The journey started when Selwyn mentioned that he had printed an RG65, and I offered to design one for him. That led to a learning process on both our parts as Selwyn experimented with printing techniques, suggested design changes to improve production, and I learned more about FreeShip’s capabilities to design interesting deck shapes.

While Selwyn enjoyed winning at the pond with our RG65, I was looking forward to the start of our racing season, including one of my favorite classes, the Footy. It wasn’t long before I had a new Footy on the drawing board, and began begging Selwyn to print for me.

The idea of designing for 3D printing was liberating for me. I’ve been a proponent of what I call “kitchen table” designs for many years. That is, I’ve enjoyed designing Footys and Rg65s that can be built on the kitchen table at low cost…but still compete at a high level. That approach, though, limited me to designing chine hulls most of the time. The 3D printer provided me with a golden opportunity to design round hulls while staying true to my convictions about simple construction and low cost.

So, naturally, the first 3D Footy had a rounded hull. It looks a bit primitive compared to our recent boats, both from a design and a production point of view. The hull design from the gunwales down was pretty sophisticated, but the deck was basically flat. We found that flat decks had two issues: First, they didn’t print all that well and tended to be wavy. Second, they tend to slow the boat when the bow goes underwater…and Footys spend a fair amount of time in that attitude! Nevertheless, my Footy performed very well, winning a regatta and proving that we were on the right track.

Our first Footys didn’t have as smooth a surface as we’d like, and required a coat of thinned epoxy inside the hull to seal pinholes and add strength. While Selwyn worked tirelessly to improve the printing, I got to work designing more interesting deck configurations, as well as experimenting with some different assembly schemes.

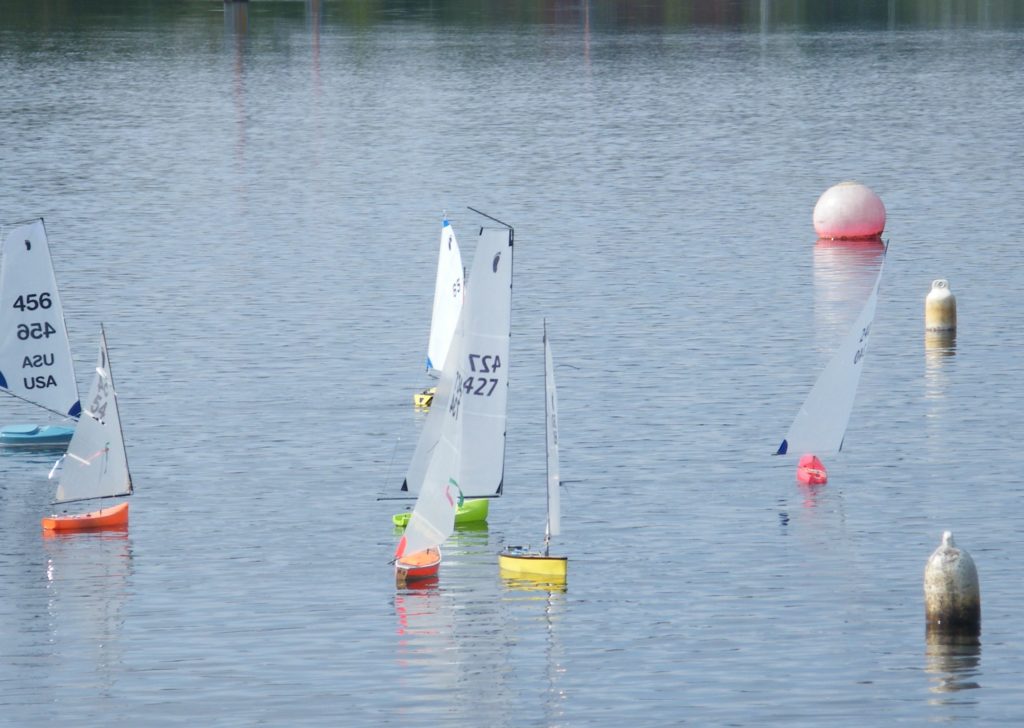

The second stage of design was more exciting than the first, with a peaked foredeck that integrated nicely with the hull shape. I have to admit, I thought it was pretty handsome. Selwyn optimistically printed several hulls. By this time, Selwyn was producing hulls with such a tight, smooth finish that no epoxy coat or sanding was needed. That was great, because I was very busy building Footys and giving them to my friends. The result was a fleet of four lovely red Footys that I called the “red tide.” They proved highly successful in competition, placing first through fourth in a highly competitive field.

Never satisfied, I wanted a change for the next regatta. Imagine being able to race a boat, decide to change it, develop a modified design, print it, build it, and sail it inside of a four week period! That is the power of the 3D printing. The longest step in the process was the seven to ten days it took the hulls to be mailed from Australia to the USA! One of these days I’ll get my own printer.

I had decided to modify the foredeck. Though I thought it looked great and performed well, I wasn’t quite satisfied with the way it came back out of the water after being submerged. The boat didn’t always come up straight, requiring quick thumbs to maintain its course.

The new design seems promising. I prefer the appearance of the red boats, but this foredeck seems to work better because of its smoother transition from the bow to the deck surface. The Green Hornet won its first race handily in our next Footy regatta, but, unfortunately, retired with a blown winch servo in race two.

That being the last regatta of the 2017 season, we’ll have to wait until next year for definitive results. Of course, by that time, Selwyn and I might have a couple of new tricks up our sleeves. Stay tuned.